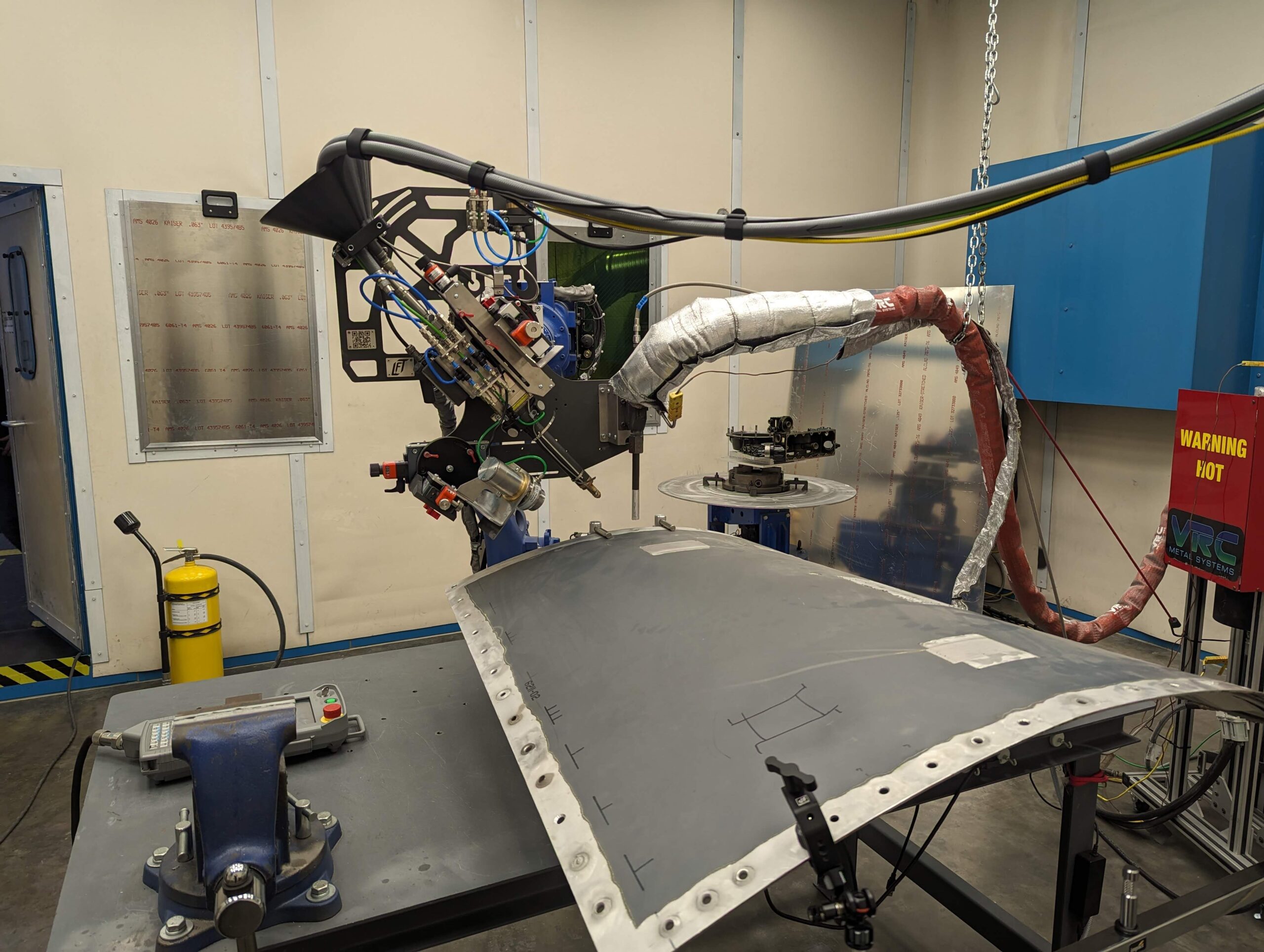

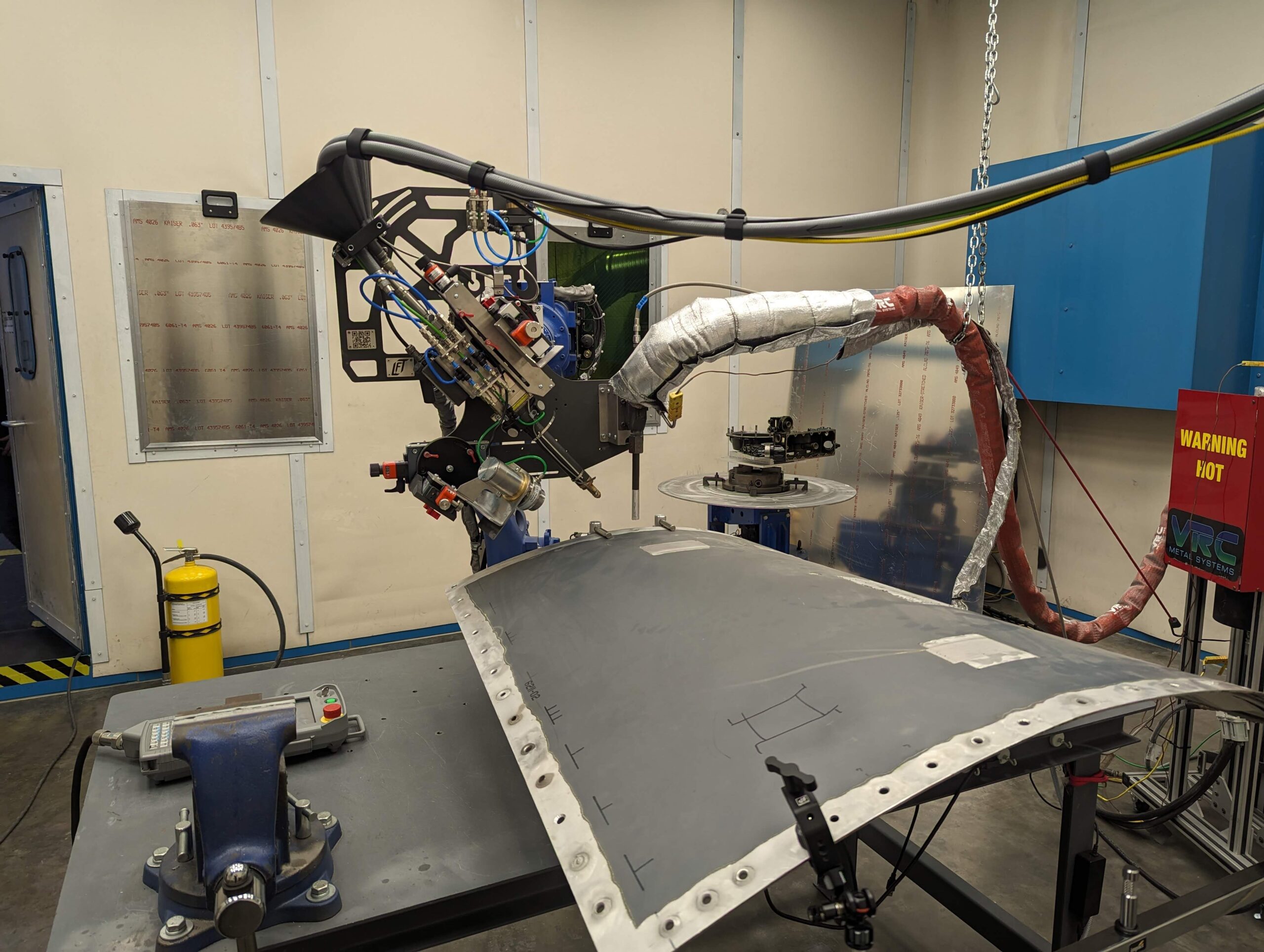

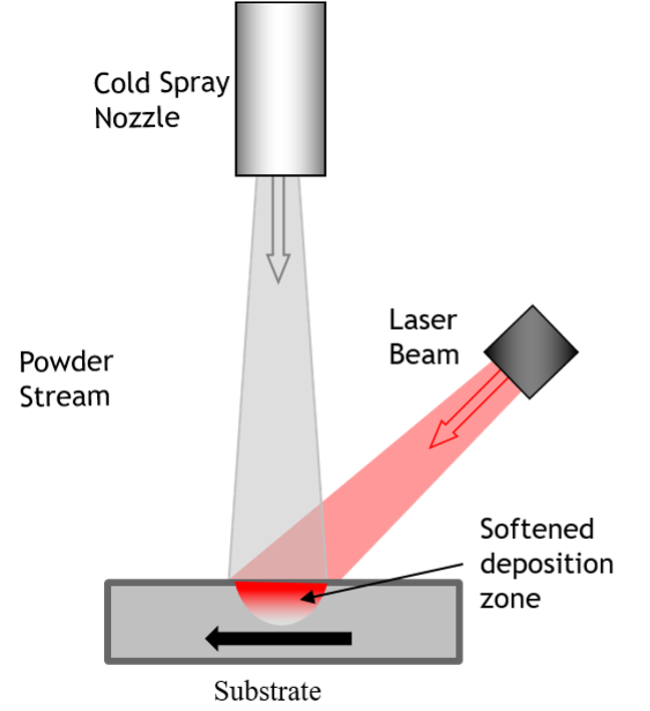

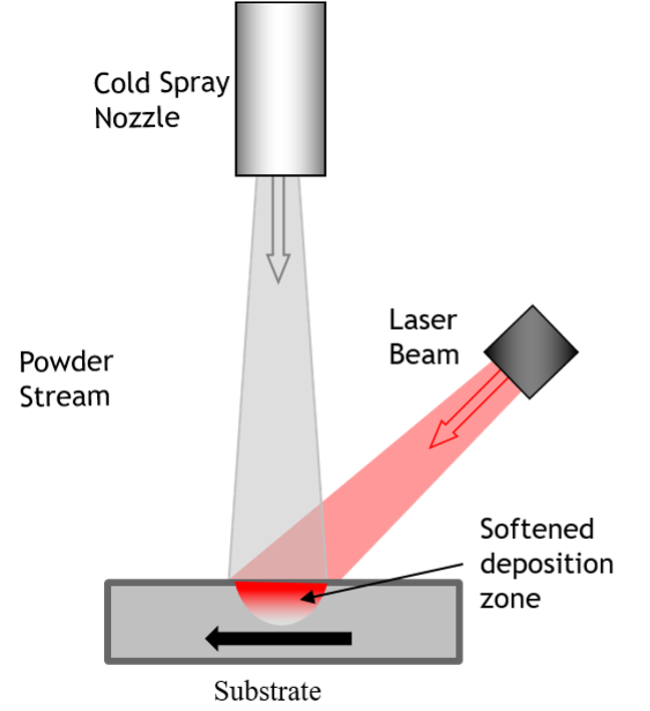

Researchers on the College of Cambridge’s Heart for Industrial Photonics have developed a brand new additive manufacturing approach known as laser-assisted chilly spray (LACS). The method combines localized laser heating with a supersonic powder stream to deposit metals and cermets for constructing, coating, or repairing components. This method addresses the high-temperature and materials limitations present in comparable methods akin to thermal spraying.

The event addresses a big price problem in chilly spray manufacturing. Conventional chilly spray processes for high-strength supplies like titanium and aluminum alloys require helium as a service gasoline, which prices roughly £80 per minute of operation. “The requirement for helium posed a big problem due to its price, which is round £80 per minute of operation. Even state-of-the-art recycling efforts recovered solely round 85% of the helium,” mentioned Professor Invoice O’Neill, who leads the analysis workforce.

LACS provides a number of technical benefits over standard chilly spray strategies. The method permits deposition at decrease particle velocities, which preserves the powder’s construction within the closing coating. It additionally operates at decrease gasoline temperatures of 400-700°C in comparison with as much as 1,200°C for traditional chilly spray, lowering energy consumption. Coatings might be utilized at charges as much as 10 kg per hour whereas sustaining the substrate under melting temperature to keep away from distortion.

The aerospace business represents a main utility space for LACS know-how. The approach permits on-demand restore and manufacturing of plane parts, probably extending plane lifespans. Conventional storage of spare components is expensive and space-intensive, and as soon as components are depleted, plane can grow to be unusable attributable to lack of alternative parts. The worldwide additive manufacturing market is projected to achieve between $70 billion and $88 billion by 2030, with the UK at the moment holding roughly 7.6% of the worldwide market.

The analysis workforce is working to boost LACS capabilities for full 3D printing purposes. Present limitations embody minimal management over powder deposition form, which restricts part-building purposes whereas remaining appropriate for coating work. “At the moment, we’ve little management over the form of deposition of the powder. This isn’t a problem for coatings however presents a big restraint for part-building purposes. Our subsequent purpose is to discover a resolution to this limitation, and we have already got some very promising outcomes,” mentioned O’Neill.

Supply: eng.cam.ac.uk