Fashionable applied sciences permit anybody not simply to be artistic at house but in addition to make unbelievable bodily issues utilizing several types of 3D printers. What’s a 3D printer? How do they work? How can this good system assist you deliver the most beautiful 3D printing initiatives to life and construct lovely figures of well-known comics and cartoon characters? Be taught extra about 3D printing expertise and how one can deliver all of your desires from the display to the actual world.

Whereas quite a few guides clarify intimately find out how to paint the fashions created with varied 3D printing strategies, some strategies are extra fashionable than others. Hobbyists who want to perceive how 3D printers work and which kind to purchase for house use primarily based on the expertise used, price, expectations, capabilities, manageability, high quality, and velocity.

3D Printing Expertise

Generally referred to as 3D printing, this expertise is also referred to as additive manufacturing or shortly AM. It makes use of 3D design initiatives to construct three-d objects by sequentially including varied supplies layer by layer. The 3D fashions which might be was bodily components are designed utilizing desktop apps and saved in CAD, STL, and different kinds of recordsdata. The preferred supplies utilized in 3D printing expertise are plastic, resin, polymers, metals, and so forth.

Although 3D printing expertise has been identified because the Eighties, it has develop into extra prevalent lately. The extra low-cost desktop machines with professional-like outcomes can be found to hobbyists, making completely different industries and small companies win from having the ability to use the extremely progressive applied sciences in interest and work. Completely different 3D printers are utilized in training, dentistry, jewellery, healthcare, engineering, manufacturing, and different fields, providing inexpensive and dependable options to many issues.

How Do 3D Printers Work?

Most 3D printing applied sciences begin with a 3D mannequin designed utilizing particular pc software program. The mannequin is saved in a file format supported by a 3D printer, which reads the file and creates its bodily copy, layering plastics, resin, sintering powder, or different supplies it helps.

To briefly describe how 3D printers work, think about a digital mannequin constructed layer by layer utilizing bodily materials, which you take away and post-process relying on its software.

Learn additionally: Greatest Free 3D Modeling Software program.

Utilizing 3D modeling software program, a designer can sculpt or create three-d fashions (utilizing scan information) that symbolize a 3D floor mathematically. Such a mission will be exported as .STL, .OBJ (two hottest recordsdata), or a unique file format to be accurately learn by 3D printing software program.

Most 3D printer sorts include their very own or help open-source software program to slice your mannequin into components which might be comfy for printing and arrange the foundations (settings) for one of the best outcome. The settings can embrace helps, supplies, mission orientation, layer top, and different particulars, which will likely be despatched over to your 3D printer by way of a USB connection or Bluetooth.

Numerous kinds of 3D printers use completely different strategies to construct the mannequin layer by layer and half by half (if a couple of), which you need to assemble your self. Some machines soften plastics that harden on the go, whereas others pour liquid resin that must be cured, fuse powder particles at excessive temperatures, and so forth. Although 3D printing applied sciences can do their work unattended, it’s suggested by no means to go away your 3D printer working in a single day or with out consideration.

Publish-processing will be guide (eradicating helps, cleansing and sanding the components, portray the mannequin, assembling the mission, and so forth.) or automated (resin will be cured in particular machines). The ultimate product will be part of manufacturing or a mildew created for funding casting and customization.

Kinds of 3D Printers

When Charles Hull created the primary 3D printer within the Eighties, not many individuals thought that 3D printing can be so inexpensive a number of a long time later. In the present day, it’s potential to spend beneath $300 and even $200 on a brand new machine. In fact, many printers nonetheless price over $1000, providing extra skilled outcomes. The value is determined by what 3D printing expertise is used, the producer, out-of-state options, half high quality, velocity, and so forth.

On this evaluate, Gambody needs to speak concerning the identified and hottest kinds of 3D printers out there out there in 2025, each for industrial and private functions.

There are 9 essential kinds of 3D printers, shortly abbreviated as:

- FDM (FFF);

- SLA;

- DLP;

- SLS;

- EBM;

- SLM;

- LOM;

- BJ;

- MJ.

It’s nice to look intently at every class primarily based on its reputation these days. We’ll additionally describe how 3D printers work to offer you a greater concept of which kind will be good on your wants.

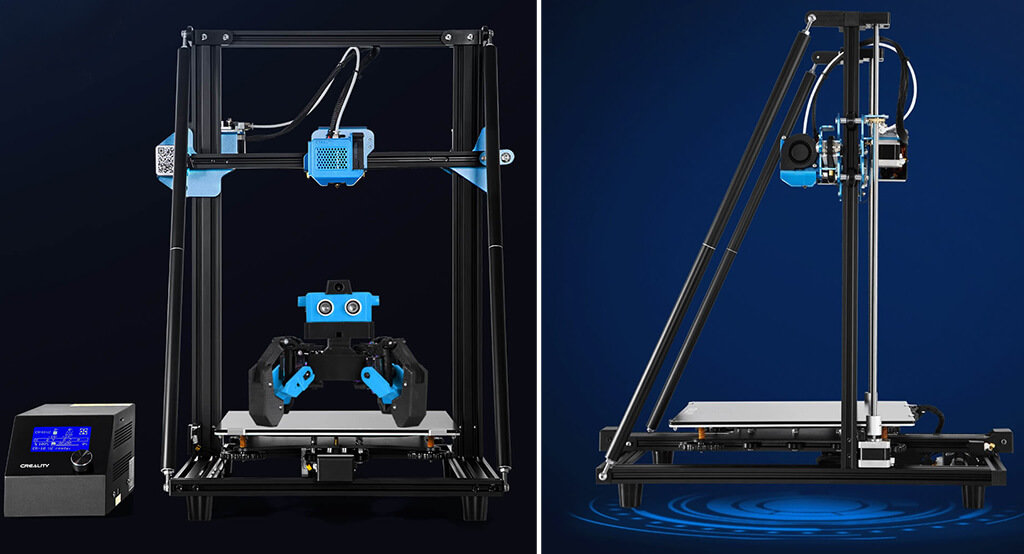

1. FDM (FFF) Kind of 3D Printers

It’s no query that FDM kinds of 3D printers are among the many hottest on the earth amongst hobbyists. They’re inexpensive by way of price and easy to function. They ship distinctive outcomes and include varied sizes of the mattress for smaller and larger initiatives.

FDM stands for fused deposition modelling, and FFF is called fused filament fabrication. They use a really comparable 3D printing expertise. Solely the names are completely different on account of logos. Thus, FDM and FFF are the identical kinds of 3D printers and will be grouped into one class.

The primary FDM 3D printer sorts had been launched by Scott Crump (Stratasys Ltd.) within the Eighties. Later, comparable 3D printing strategies had been provided beneath the FFF abbreviation. Each FDM/FFF units proved to be very practical and provided excellent print high quality.

FDM/FFF kinds of 3D printers work with thermoplastics, constructing fashions layer by layer by heating plastic to its melting level and extruding filament by the nozzle onto the print mattress. This printing technique can depend on helps whereas constructing a mannequin, and there are a number of kinds of helps utilized by FDM machines.

The printing velocity relies upon very a lot on the dimensions of the mannequin and the nozzle diameter.

Worth begins at: $149 – $199.

Customary filament: ABS, PLA.

Well-known FDM 3D printers: Creality CR-10, Prusa i3 MK2, Creality Ender-3, ANYCUBIC Chiron, FlashForge Creator Professional.

Learn additionally: The Greatest Ender-3 Upgrades to Create Improbable 3D Prints (V2, Professional, Neo, V3 KE, S1, MAX).

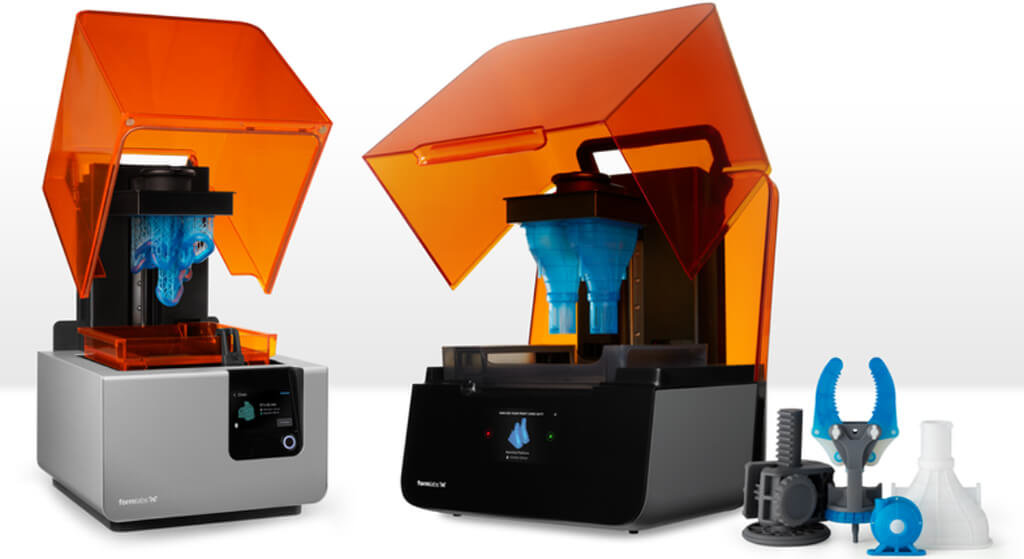

2. SLA Kind of 3D Printing

The historical past of 3D printing started with SLA kinds of 3D printers invented by Charles Hull from 3D Techniques, Inc. In the present day, this expertise continues to be used broadly.

SLA stands for stereolithography equipment, which makes use of a prototyping course of and depends on ultraviolet mild. This technique is ideal for each skilled engineers and home-made fanatics.

SLA machines can flip liquid plastic into properly stable fashions by exposing the liquid and forming the layer of the mannequin with the laser. When the layer is accomplished and the plastic turns into exhausting, the machine provides a fraction of liquid to let the laser type one other layer. With all layers completed, it’s a should to rinse a 3D printed determine with a solvent and course of the mannequin in an ultraviolet oven.

The standard of prints often is determined by the standard of the SLA machine. The mannequin may not be too clean if a low-cost system is used.

Whereas many individuals use SLA laser machines to make prototypes somewhat than completed objects, many hobbyists can print spectacular fashions utilizing this 3D printing expertise.

Worth begins at: $199 – $249.

Frequent 3D printing materials: Resin.

Well-known SLA 3D printers: Formlabs Kind 2, Monoprice MP Mini, and ANYCUBIC Photon S.

Learn additionally: Greatest Resin Printing Suggestions for Orienting Fashions on SLA/DLP/LCD 3D Printers.

3. DLP Sorts of 3D Printers

The DLP 3D printing expertise (DLP is digital mild processing) was developed within the Eighties, simply as FDM and SLA had been. Much like SLA, DLP, it additionally wants photopolymers to work.

These projectors often use arc lamps for mild, work with liquid plastic resin, and have a particular liquid crystal show panel. They have an effect on resin with mild to form it within the type of the printed mannequin, layer by layer, with every being uncovered solely suddenly.

The velocity with which new fashions are constructed is spectacular. Whereas DLP projectors are costly, they’re stylish in jewellery, dental, and different microstructure industries.

Worth begins at: $1,000 – $3,500.

Customary 3D printing materials: Resin.

Well-known DLP 3D printers: MiiCraft 125, EnvisionTEC P4K, and Wanhao Duplicator 8.

Learn additionally: What Is DLP/SLA Eco Model of 3D Printing Information and How It Saves Resin.

4. SLS 3D Printer Sorts

It’s potential to create lovely fashions with SLS or selective laser sintering 3D printing method. SLS machines have existed because the Eighties, identical to many different kinds of 3D printers.

In some methods, SLS expertise is much like SLA. These machines work with powdered materials, in contrast to SLA printers that require liquid resin.

SLS machines require no helps throughout 3D printing. Powder surrounds every mannequin that’s crafted on such a tool. Because the machine can work with varied supplies, together with silver steel, it’s stylish amongst firms and people who provide custom-made 3D printed merchandise (jewellery, equipment, and so forth.).

On the similar time, the pricing level is fairly excessive due to the CO2 lasers utilized in units. Such high-power lasers can fuse particles because the laser is scanning layers.

Costs begin at: $6,000 – $10,000.

Frequent materials: Powdered substances (nylon, ceramics, metals).

Well-known SLS 3D printers: Sinterit Lisa Professional, Formlabs Fuse 1.

Uncover premium 3D printing figures on Gambody market.

5. SLM 3D Printing Applied sciences

Corporations that have to soften metals into 3D-dimensional components work with SLM or selective laser melting 3D printing expertise. Such machines have a high-power laser beam. This laser can fuse and soften metallic powder materials and type extremely detailed fashions.

The primary SLM machines had been invented again in 1995.

Utilizing .STL recordsdata, like many different 3D printers, SLM machines evenly distribute steel powder onto the print mattress. Then, excessive laser power is utilized to each printable layer to fuse it. Fashions are fashioned from the melting powder, layer by layer.

Whereas SLM sorts of 3D printers are good for crafting advanced steel buildings and broadly utilized in aerospace and medical industries, they aren’t fashionable amongst at-home fanatics on account of their costly price.

Costs begin at: $250,000 – $400,000.

Frequent materials: Steel powder.

Well-known SLM 3D printers: SLM 500, SLM Options SLM 125, Optomec LENS 450, and Realizer SLM 125.

Learn additionally: Gorgeous 3D Printer Designs (25 Greatest 3D Print Information).

6. EBM 3D Printing Strategies

Developed quickly after the invention of SLM machines, EBM (electron beam melting) boasts comparable 3D printing expertise. A lot of these 3D printers additionally work with metals and apply powder mattress fusion processes whereas constructing a mannequin.

EBM machines work at excessive temperatures as a result of they soften the steel powder to the fullest. The printing velocity is fairly sluggish. The selection of steel powder is minimal. It’s what makes the EMB method unpopular even amongst producers.

On the similar time, some firms within the aerospace and medical industries efficiently apply EBM kinds of 3D printing of their work.

Costs begin at: $250,000.

Frequent materials: Steel powder.

Well-known EBM 3D printers: Arcam Q20 and Q20plus.

Obtain STL recordsdata of the most well-liked spacecraft 3D printing fashions on Gambody market.

7. LOM Kinds of 3D Printing

Whereas LOM machines (LOM stands for laminated object manufacturing) should not fashionable amongst hobbyists and crafters, these kinds of 3D printers are a number of the quickest. They’re additionally probably the most inexpensive by way of supplies used.

The LOM technique makes use of layers of paper (or steel, plastic) and adhesive to fuse them. All the things works beneath warmth and stress, and the ultimate shapes will be fashioned by utilizing a knife or laser. It might probably require further processes afterward, for instance, drilling or machining.

Whereas utilizing paper and glue to create 3D printing objects is unbelievable and such a way is environment-friendly, LOM machines are expensive.

Costs begin at: $4,000 – $40,000.

Frequent materials: Paper.

Well-known LOM 3D printers: Mcor ARKePro, Mcor Matrix 300+, Iris HD, Solido SD300 Professional.

Learn additionally: Over 100 Enjoyable 3D Printer Initiatives.

8. BJ 3D Printing Sorts

If you hear about inkjet 3D printing applied sciences, BJ or binder-jetting is what is supposed. This expertise makes use of powder-based materials along with a bonding agent to create varied initiatives.

The machine builds layer by layer, attaching them with an adhesive. Whereas such 3D printing strategies don’t assure any high-resolution prints, they’ll create colourful initiatives should you provide the binder with colour pigments.

BJ 3D printer sorts often concentrate on one specific materials. Some work with steel solely, others are nice for printing with sand, and so forth.

Costs begin at: $250,000.

Frequent materials: Powder-based plastics, sand, gypsum, ceramics, metals.

Well-known BJ 3D printers: X1 160PRO, ExOne R2 steel 3D printer.

Learn additionally: Greatest 3D Printers Underneath 1000 USD.

9. MJ Expertise

This expertise differs lots from all different 3D printing sorts. It’s best described not as MJ or materials jetting however as wax casting. Whereas wax casting has existed for hundreds of years because of jewellery customization, MJ expertise turned part of the 3D printing world not so way back. It turns wax casting into an automatic process.

MJ kind of 3D printing is typical for the jewellery and dental industries, the place it’s required to construct high-resolution fashions and casts.

The machine heats the wax and provides it to the print mattress, layer by layer, which is cured by UV lights.

Costs begin at: $70,000.

Frequent materials: Artificial waxes.

Well-known MJ 3D printers: ProJet MJP 3600.

FAQ

1. What kind of producing is 3D printing?

3D printing expertise is additive manufacturing (AM).

2. What’s a 3D printer?

A 3D printer constructs a three-d determine or mannequin from a digital 3D or CAD mannequin.

3. What kinds of 3D printers are there?

There are 9 essential kinds of 3D printers. They’re FDM (FFF), SLA, SLS, DLP, EBM, SLM, LOM, BJ, and MJ.

4. What to learn about 3D printers?

3D printing helps you to create just about something. Your creativeness is the one limitation you’ve gotten with this manufacturing course of that lays down the fabric (plastic, resin, steel, sand, and so forth.) layer by layer, forming a three-d determine or mannequin.

These are the primary kinds of 3D printers utilized in 2025. Many 3D printing applied sciences are designed and utilized by firms and massive firms in dental, jewellery, aerospace, and different industries. They’re costly for at-home utilization. Nonetheless, there are lots of inexpensive FDM (FFF), SLA, and SLS machines most popular by hobbyists from all around the world.

Regardless of which 3D printer sorts you favor and run to construct fashions, make certain to share pictures of the initiatives you might be most happy with with Gambody Fb group. It’s a place to publish 3D prints, comply with recommendation on portray, and seek for invaluable suggestions and tips.

(Visited 3,139 instances, 1 visits at the moment)