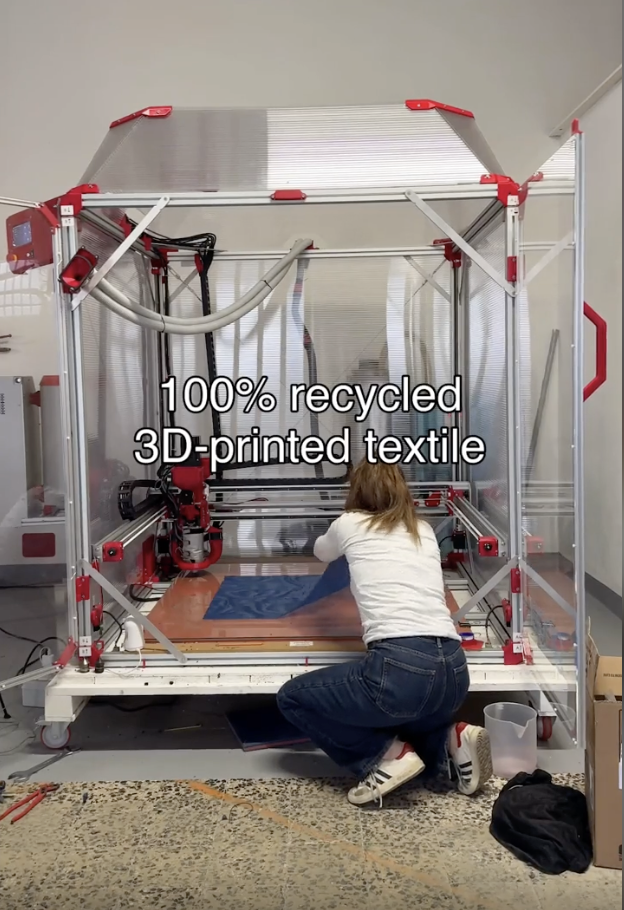

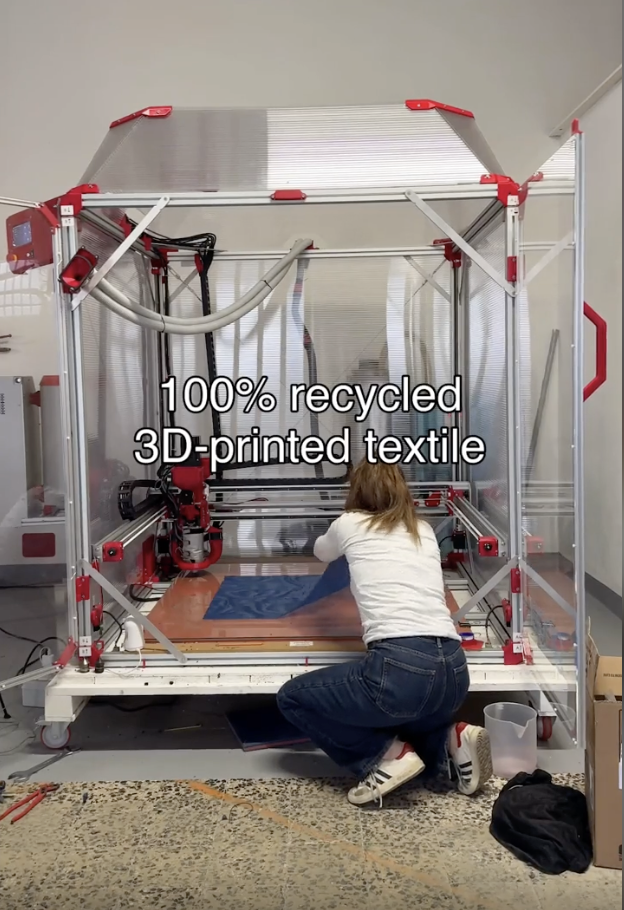

Designer Danit Peleg has launched an experimental course of for changing denim waste into a completely recycled, 3D printable textile, unveiling the early-stage work at Denim Première Imaginative and prescient in Milan.

The undertaking begins with manufacturing scraps sourced from Italian producer PureDenim, recognized for its sustainability-focused denim improvements. The waste is shredded into fibers, blended with 100% recycled TPU, and extruded into pellets appropriate for large-format additive manufacturing. Utilizing a Ginger Additive printer, Peleg’s staff produced a 70 × 70 cm textile pattern in below half-hour.

Working with engineer Victor Gagneux, Peleg examined a number of textile buildings, denim-to-TPU ratios, and print parameters, encountering quite a few failures earlier than reaching what she describes as their first “100% recycled 3D printed denim textile.” Whereas the preliminary result’s imperfect, she says the fabric reveals sturdy potential: it may be printed to form, on demand, and with no extra materials—supporting a extra round manufacturing mannequin.

Business Response and the Recycling Debate

The designer’s LinkedIn put up sparked each enthusiasm and concern. Some commenters questioned whether or not a mixture of cotton and TPU—regardless of each being recycled—could possibly be successfully recycled once more. When requested, “WHO can Recycle the Mixture of Cotton and TPU?” Peleg maintained that she believes it’s potential.

Others have expressed pleasure in regards to the prospect of manufacturing advanced textile buildings or clothes by way of this hybrid 3D printing strategy. “Turning denim waste into 3D printed textiles opens up an entire new chapter for round design,” mentioned Repriya Raj Poddar, Founder at PAAKHI.

3D Printing and Sustainability Throughout Trend

Peleg’s work is a part of a broader pattern of vogue manufacturers embracing additive manufacturing for each artistic freedom and sustainability. Sydney-based label Amiss debuted at WINGS 2025 with a assortment impressed by pure varieties akin to seashells and the Australian bush. Utilizing Creality’s 3D printing ecosystem—together with scanners, printers, filaments, and laser cutters—the model accelerated its workflow, producing detailed items in hours quite than weeks. Founders Vanessa and Josh credit score 3D printing with enabling sooner prototyping, larger artistic management, and a extra sustainable, unbiased design mannequin.

Equally, the New York Embroidery Studio (NYES), recognized for high-profile initiatives just like the MET Gala, adopted the Stratasys J850 TechStyle, the world’s first 3D printer designed for direct textile printing. The system permits NYES to provide intricate, tactile designs whereas enhancing workflow effectivity and minimizing materials waste. Proprietor and inventive director Michelle Feinberg highlighted the expanded artistic prospects, whereas Stratasys senior VP Zehavit Reisin emphasised the sustainability advantages of on-demand manufacturing and lowered surplus stock.

The 3D Printing Business Awards are again. Make your nominations now.

Do you use a 3D printing start-up? Attain readers, potential traders, and clients with the 3D Printing Business Begin-up of 12 months competitors.

To remain updated with the newest 3D printing information, don’t overlook to subscribe to the 3D Printing Business publication or comply with us on Linkedin.

Featured picture reveals Prototype for 3D Printed Denim Made From Recycled Waste. Picture by way of Danit Peleg.