Safe your spot now for unique AM insights at our Additive Manufacturing Benefit on-line convention masking aerospace, area, and protection!

Requirements developer ASTM Worldwide has partnered with Nikon Superior Manufacturing (Nikon AM) to assist strengthen the US protection provide chain, with a twin deal with workforce readiness and superior manufacturing capabilities.

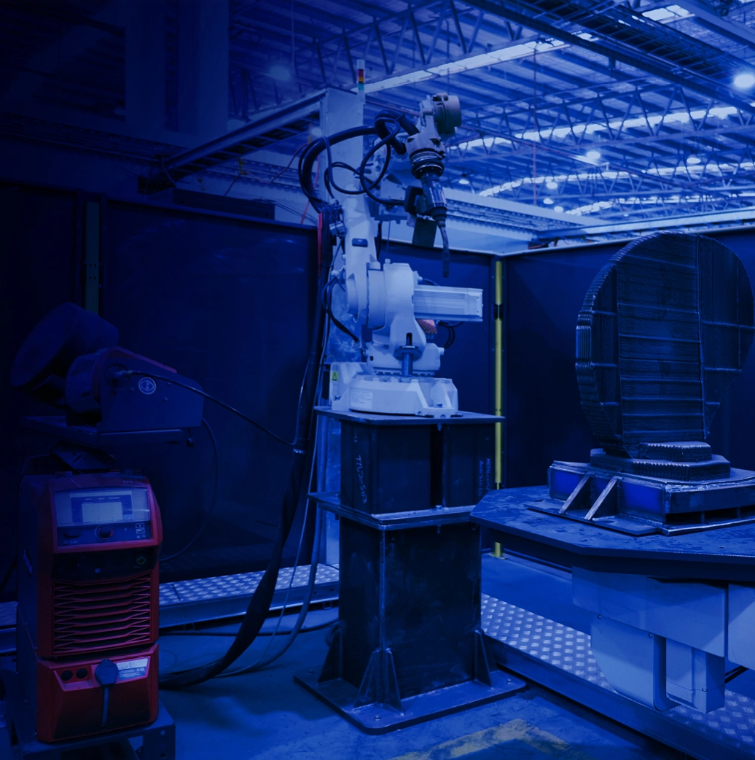

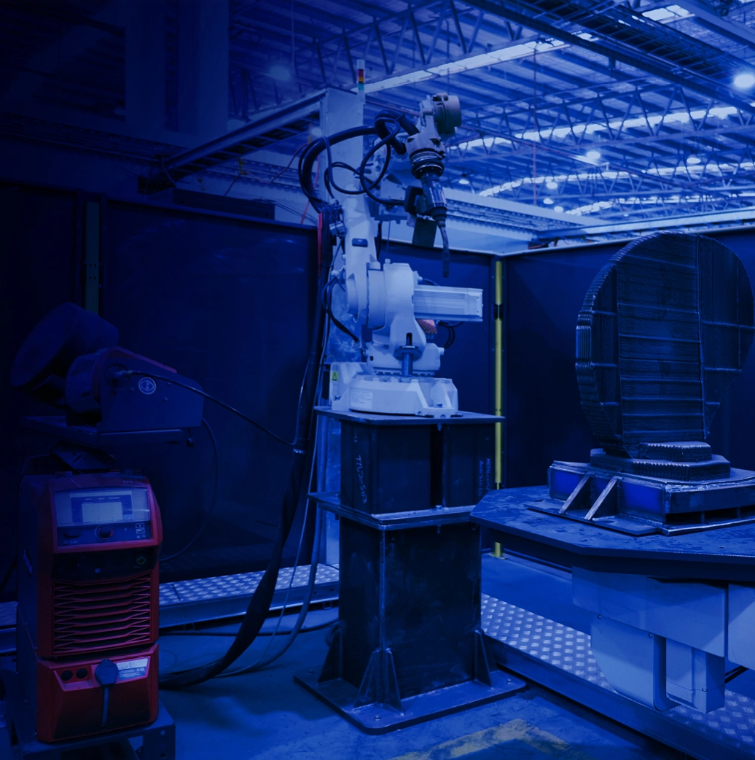

The settlement formalizes a joint effort to develop specialised coaching and certification packages for defense-focused manufacturing roles, starting with initiatives tailor-made to the wants of the US Navy. Coaching will happen at Nikon AM Expertise Heart in Lengthy Seashore, California which is supplied with giant format laser powder mattress fusion methods (LPBF), in addition to in-house experience in metallurgy and precision measurement.

As a press release, Andrew G. Kireta, Jr., President of ASTM Worldwide, mentioned, “This collaboration with Nikon AM brings collectively two establishments with unmatched legacy and world recognition. Collectively, we’re reinforcing the connection between workforce improvement, resilient provide chains, and nationwide safety—all whereas serving to speed up the adoption of superior manufacturing at an industrial scale.”

Bridging expertise and supplies for army manufacturing

The partnership follows a latest announcement by Nikon to deepen its position in U.S. protection and aerospace manufacturing. Final month, Nikon AM signed a improvement settlement with the Nationwide Heart for Protection Manufacturing and Machining (NCDMM) to assist a government-funded effort centered on qualifying Constellium’s Aheadd CP1 aluminum alloy for thermal administration parts.

Funded by the Workplace of the Beneath Secretary of Protection, the $2.1 million program brings collectively a number of key gamers within the protection manufacturing area, together with ASTM Worldwide and technical specialists from Lockheed Martin, Northrop Grumman, RTX, Common Atomics, and Honeywell Aerospace. As a part of the initiative, Nikon AM is evaluating the fabric’s efficiency and contributing to a shared supplies database supposed to information future purposes in protection and aerospace methods.

Constructing on that momentum, the 2 organizations plan to pursue federally funded analysis, with Nikon AM contributing by way of its position in ASTM occasions such because the Worldwide Convention on Superior Manufacturing (ICAM) and associated workshops on manufacturing requirements and protection manufacturing strategies.

The settlement outlines how the 2 sides will proceed working collectively whereas defending mental property (IP). Alongside Nikon’s ongoing supplies validation work, the partnership brings collectively schooling, analysis, and manufacturing priorities inside the broader US protection manufacturing panorama.

Momentum throughout protection manufacturing initiatives

The collaboration between ASTM and Nikon AM is the newest in a sequence of AM initiatives aiming to enhance the US Navy’s provide chain resilience and onshore manufacturing capabilities.

Final 12 months, Australian 3D printer producer AML3D secured an AUD$0.70 million (US$0.46 million) order from Laser Welding Options (LWS) for 2 ARCEMY Small Version 2600 3D printers, leased for 12 months with an choice to buy. The deal included software program licensing and technical assist, with the printers set to ship from Adelaide to Houston and turn into operational inside 8 to 10 weeks.

These Wire Arc Additive Manufacturing methods joined an present ARCEMY unit acquired by LWS in 2023 and aimed to speed up qualification of Nickel Aluminum Bronze parts for the US Navy’s submarine provide chain as a part of AML3D’s ‘Scale-Up’ technique.

Earlier than this, Bechtel Plant Equipment Inc. (BPMI) adopted Velo3D’s steel AM system to assist the U.S. Naval Nuclear Propulsion Program, deciding on the Sapphire XC 3D printer configured for stainless-steel 415. The system was put in at supplies firm ATI’s facility close to Fort Lauderdale, the place it will be used to streamline manufacturing of advanced parts beforehand made by way of casting.

By decreasing the necessity for intensive assist buildings, Velo3D’s expertise enabled quicker and extra versatile manufacturing of large-format components. The collaboration gave ATI the power to supply intricate geometries with larger effectivity, strengthening the availability chain and serving to tackle long-term upkeep challenges throughout the Navy’s growing old fleet.

What 3D printing traits do you have to be careful for in 2025?

How is the way forward for 3D printing shaping up?

To remain updated with the newest 3D printing information, don’t neglect to subscribe to the 3D Printing Trade e-newsletter or observe us on Twitter, or like our web page on Fb.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture exhibits a US Navy submarine. Photograph by way of the Naval Sea Methods Command (NAVSEA).