3D Printing Business not too long ago visited HLH Speedy to talk with James Murphy, Co-Founding father of HLH Prototypes and Director of HLH Speedy, and be taught extra in regards to the firm’s world manufacturing capabilities.

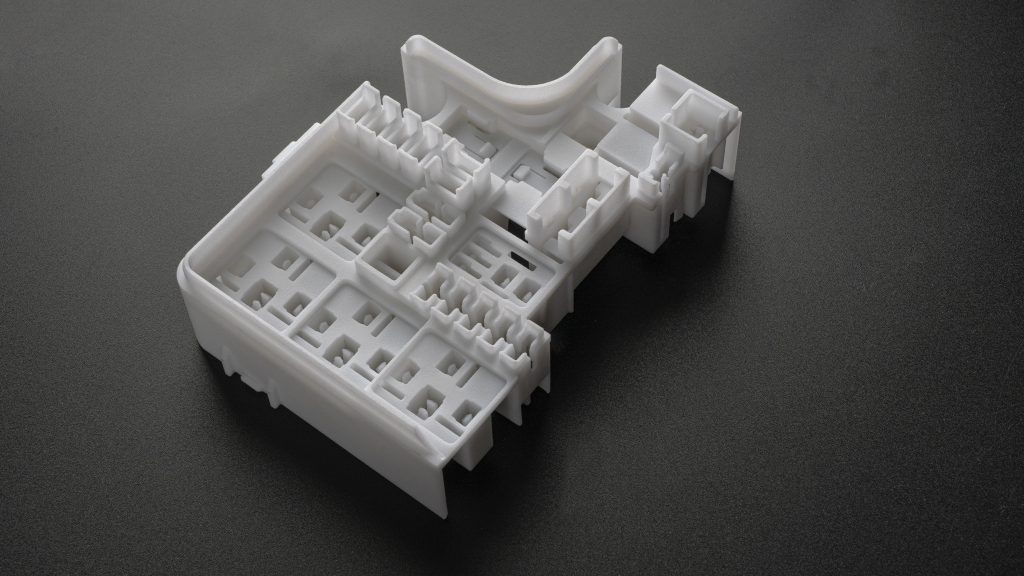

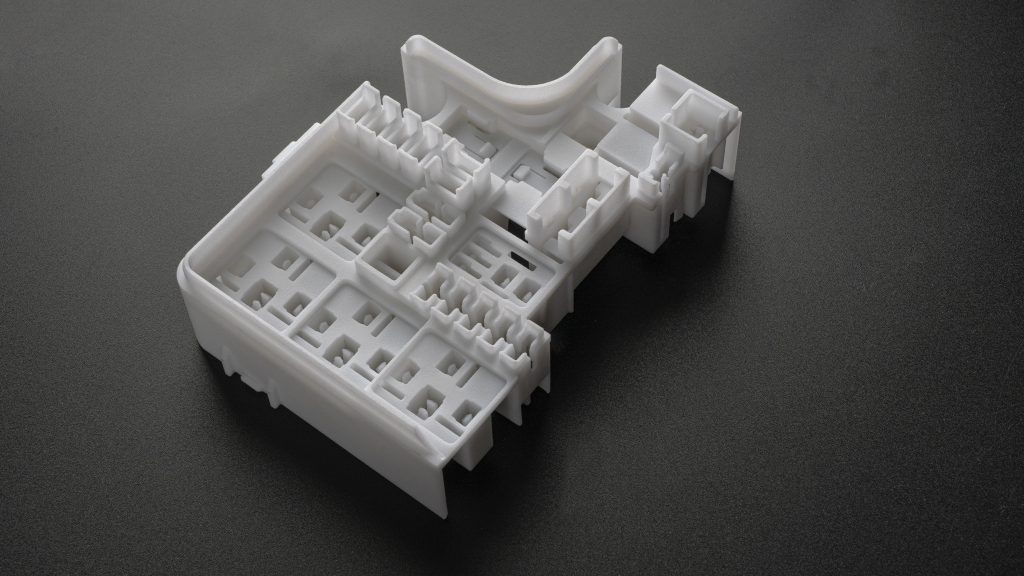

Based in China in 2008, HLH Prototypes is a producing service bureau specializing within the fast prototyping and high-mix, low-volume manufacturing of components. The corporate provides a variety of producing applied sciences, together with each metallic and polymer 3D printing, CNC machining, injection molding and tooling, die casting, and vacuum casting.

The overwhelming majority of the corporate’s manufacturing is carried out from 4 services in China, the biggest of which is predicated in Guangdong, Shenzhen, and spans 4,000 square-meters. The European arm of the corporate, HLH Speedy, was based in 2021 and is headquartered in Leeds, UK.

Linking western companies with Chinese language manufacturing

With a background in journalism and movie manufacturing, Murphy’s journey into fast manufacturing has been something however standard.

“My background is just not actually in manufacturing in any respect,” defined Murphy. “Once I was youthful I went to China on vacation, and I believed it was wonderful. The sense of hope and alternative that everyone has on the market was actually interesting. So I got here again, stop my job, and moved there.”

Murphy initially labored within the engineering division of an organization that manufactured HDMI and USB cables. There, he first realized the right way to use CAD software program and design programmes, which ultimately led him to maneuver to a prototype manufacturing firm. Murphy defined that, after six months, the possession of this firm modified palms.

“My outdated boss requested me if I fancied beginning one other firm with them. It appeared like an thrilling alternative, so we began the corporate HLH. The concept was to hyperlink up western enterprise with Chinese language manufacturing,” acknowledged Murphy. “In 2010 we opened our first manufacturing unit, and since then we’ve been rising pretty steadily.”

The corporate now employs over 300 individuals. What’s extra, HLH has since grown its world attain additional with the launch of HLH Speedy in 2021.

The choice to open a HQ within the UK, Murphy defined, was pushed by a mix of non-public and business-related elements. “I lived in China for 15 years, and after I first moved there I used to be simply having lots of enjoyable. We had been constructing an organization, and it was all go, go, go.” Nonetheless, after having kids Murphy determined to go again to Leeds, the place he had himself grown up.

Moreover, Murphy acknowledged that the choice to open a UK-based subsidiary has strategic benefits. “I believe it’s actually helpful for us to have this location right here as a result of over 80% of all of the work we’re doing is for firms in Europe and North America,” commented Murphy. “There are many benefits to being nearer to them and with the ability to go to them simpler and have conversations face-to-face. In order that’s why we opened this place up.”

A collection of producing applied sciences

HLH provides a broad vary of producing applied sciences. When the corporate launched, it specialised within the manufacturing of prototypes utilizing conventional manufacturing processes. “Once we first began, we produced very low quantity components, primarily utilizing CNC machining and vacuum casting,” defined Murphy. “At the moment, additive manufacturing was very, very costly.”

Nonetheless, based on Murphy, the value of 3D printers in China started to drop as patents expired, permitting home firms to fabricate their very own 3D printing tools and supplies. “Once we first began, an industrial SLA 3D printer may need price round £250,000, however now you may get one for £20,000,” acknowledged Murphy. “That drop in price simply opened the entire business up in China. Between 2012 to 2015, it actually began to take off.”

As such, HLH has since adopted quite a lot of industrial 3D printers, together with SLA, SLS, FDM, Multi Jet Fusion (MJF), and metallic laser sintering. The corporate now has round 100 3D printers, with 99.9% of all manufacturing being fulfilled in China. “Right here within the UK, we’ve three desktop 3D printers that we solely use for our personal private necessities, or if a buyer wants one thing the subsequent day.”

Moreover MJF expertise from multinational printing agency HP, nearly all of HLH’s 3D printers are Chinese language-built. Many of the firm’s SLA 3D printers are from UnionTech, while nearly all of their SLS and metallic sintering machines are from Farsoon Applied sciences.

In accordance with Murphy, regardless of being considerably extra reasonably priced, these 3D printers provide just about the identical 3D print high quality as their western-made counterparts. “By way of the components popping out, it’s just about corresponding to what individuals are utilizing within the west, like 3D Methods’ 3D printers. There’s not likely any sort of distinction within the high quality of the components,” acknowledged Murphy. “If you may get one thing that’s nearly pretty much as good for a 3rd of the value, you may as properly do it.”

Addressing a variety of purposes beneath one roof

Offering this intensive suite of each conventional and additive manufacturing expertise all beneath one roof is alleged to supply vital benefits. “Every completely different expertise has its execs and cons. Every course of has its personal distinctive benefits” defined Murphy. “We work with a large vary of consumers, tasks and purposes. So, it is sensible for us to have a number of completely different applied sciences to fulfill all of their completely different wants.”

HLH offers prototype and end-use components to over 3000 firms in 50 nations. Murphy emphasised that these components span a broad vary of ever-changing purposes. “The demand is all the time altering, so what we manufacture actually is determined by what the subsequent massive factor is,” defined Murphy.

As such, the corporate is presently producing lots of components for clear vitality, vitality storage, and waste discount purposes. “They’re bringing lots of new expertise, and lots of it’s within the early analysis and growth (R&D) stage.”

Elsewhere, HLH has seen demand inside robotics, medical and biomedical, autonomous car industries. “This business is admittedly good as a result of we see demand in no matter’s new, and that’s what we work on,” added Murphy.

Murphy additionally views high-mix, low-volume 3D printing capabilities of HLH as including worth to clients. “The flexibility to make adjustments and manufacture bespoke components with complicated geometries is necessary for us,” defined Murphy. “There’s all the time purposes the place additive manufacturing is an efficient choice. Because the expertise develops additional, and because the supplies develop, the potential use-cases will even enhance fairly significantly.

Differentiating inside on-demand manufacturing

Murphy highlighted key opponents throughout the business as being different manufacturing bureaus akin to Protolabs, Xometry, and Hubs. Nonetheless, based on Murphy, HLH differentiates from these opponents. “We provide one thing a bit of bit completely different to them due to how lengthy we’ve been doing it, and the way the corporate is about up,” defined Murphy.

Certainly, when in comparison with Xometry, Murphy highlighted the direct relationship HLH provides to its clients as being a key differentiator. “Primarily, we’re the producer. So, as a substitute of speaking to a intermediary, the client can discuss on to the individuals who really make the half. I believe that makes a giant distinction.”

Murphy additionally pointed to the “buyer dealing with” assets on the web site hlhrapid.com as including worth. Right here, clients can entry informative movies, design guides, and even digital and reside excursions of the corporate’s services. “We attempt to make the web site a useful resource moderately than simply a web based brochure,” defined Murphy.

The way forward for HLH

Murphy hopes that “the long run seems pretty just like the previous,” with HLH persevering with to see regular progress. “For us, we simply need to stick with it doing what we’re doing, do it in addition to we are able to, and keep on the forefront of the several types of applied sciences and processes which might be obtainable.”

By way of progress globally, Murphy famous that the corporate hopes to develop HLH Speedy additional throughout the UK. While this progress is taking a bit of longer than had been initially anticipated, the medium to long-term purpose is to increase HLH’s manufacturing capabilities within the UK and ultimately North America.

Subscribe to the 3D Printing Business publication to maintain updated with the most recent 3D printing information. You too can observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing business? Go to 3D Printing Jobs to view a collection of obtainable roles and kickstart your profession.

Featured picture reveals James Murphy, Co-Founding father of HLH Prototypes and Director of HLH Speedy. Picture by 3D Printing Business.

![[INTERVIEW] HLH Speedy: fast prototyping and high-mix, low-volume manufacturing beneath one roof [INTERVIEW] HLH Speedy: fast prototyping and high-mix, low-volume manufacturing beneath one roof](https://3dprintingindustry.com/wp-content/uploads/2024/01/HLH-Rapid-Co-Founder-and-Director-James-Murphy.-Photo-by-3D-Printing-Industry-scaled.jpg)