A crew of Europe-based researchers has developed a novel holographic 3D Printing technique. The group created a modified Tomographic Volumetric Additive Manufacturing (TVAM) method able to shortening 3D printing occasions to mere seconds whereas rising effectivity.

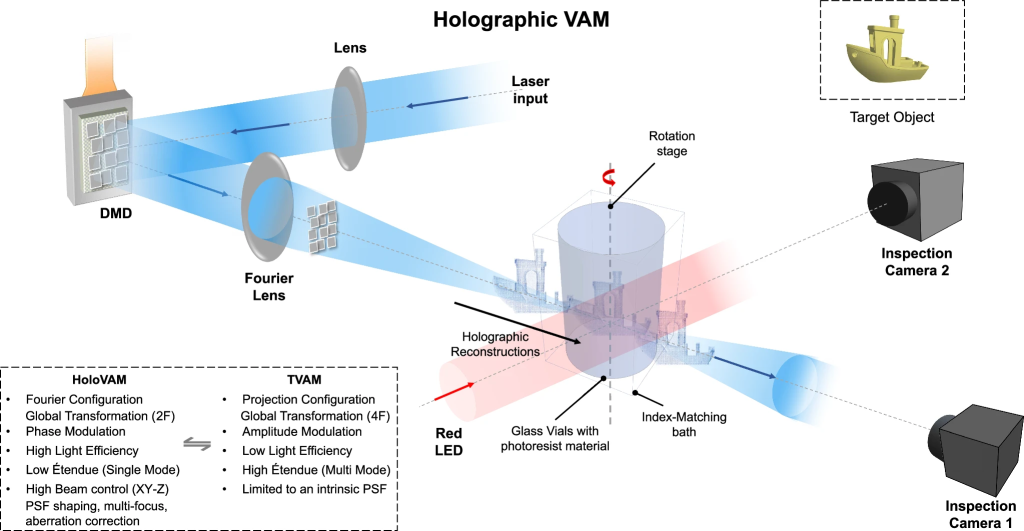

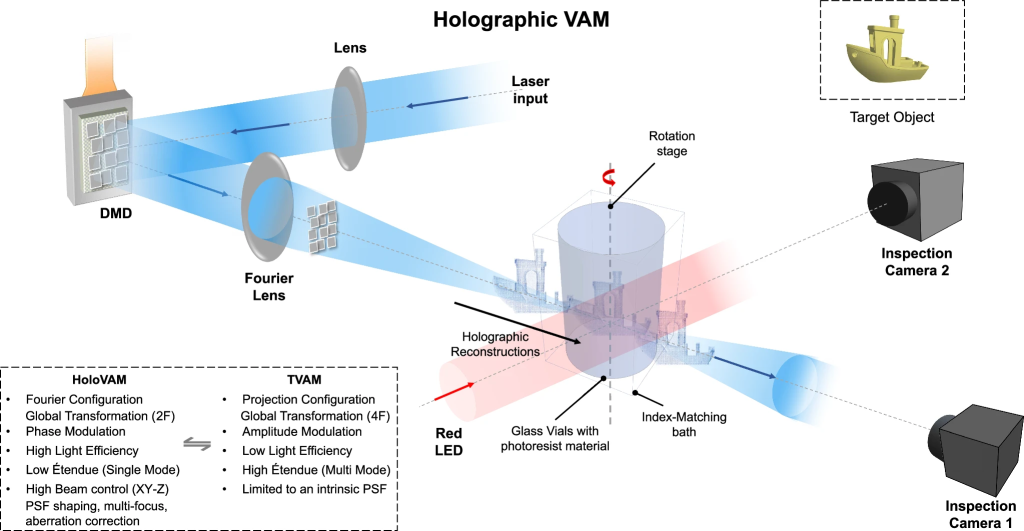

Not like typical layer-by-layer 3D printing strategies, TVAM can create total objects in a single shot by shining mild patterns into liquid resin, which solidifies when the sunshine depth is excessive sufficient. Whereas this method can fabricate support-free, micro-scale components inside tens of seconds, it’s “extremely inefficient.” It’s because beneath 1% of the encoded mild reaches the resin vial. Standard TVAM may result in undesirable distortions and poor decision as a consequence of mild blurring and projection artifacts.

To deal with these limitations, the researchers developed HoloVAM, a brand new method that makes use of a 3D hologram as an alternative of typical volumetric mild projections. This method reportedly boosts mild effectivity by 20 occasions, leading to sooner and extra correct 3D printing. In response to their paper, revealed in Nature Communications, HoloVAM efficiently fabricated a number of millimeter-scale objects in beneath 60 seconds with advantageous particulars as small as 31 micrometers.

The scientists behind the invention are based mostly between the Laboratory of Utilized Photonic Units at Switzerland’s EPFL and the College of Southern Denmark’s Centre for Photonics Engineering. They consider this new method affords worth for medical bioprinting functions, because of HoloVAM’s use of “self-healing beams.” These can generate and retain their form when passing via supplies, which is especially beneficial when 3D printing with cell-laden bio-resins and hydrogels.

Holographic 3D printing enhances pace and effectivity

A key problem in current TVAM approaches is effectivity. Most mild is misplaced, losing power and lowering 3D printing accuracy. To sort out this, the researchers used a hologram tiling method known as HoloTile. Invented by College of Southern Denmark professor Jesper Glückstad, this method breaks the 3D hologram of the specified half into smaller tiled sections. It really works by projecting a number of detailed holograms into the resin, which solidifies the place the sunshine is most intense.

A key problem in holographic projections is “speckle-noise,” undesirable patterns attributable to laser mild interference. To get rid of this, the HoloTile system quickly shows holographic patterns as much as 22,000 per second. Moreover, the laser beam’s part is adjusted to interrupt up noise patterns, whereas specialised Bessel and vortex beams present extra secure mild distribution. Not like conventional 3D printing, which constructs objects layer by layer, HoloTile leverages a rotating resin veil. This steady movement shifts the speckle sample, naturally blurring out noise and leading to easy edges and advantageous particulars.

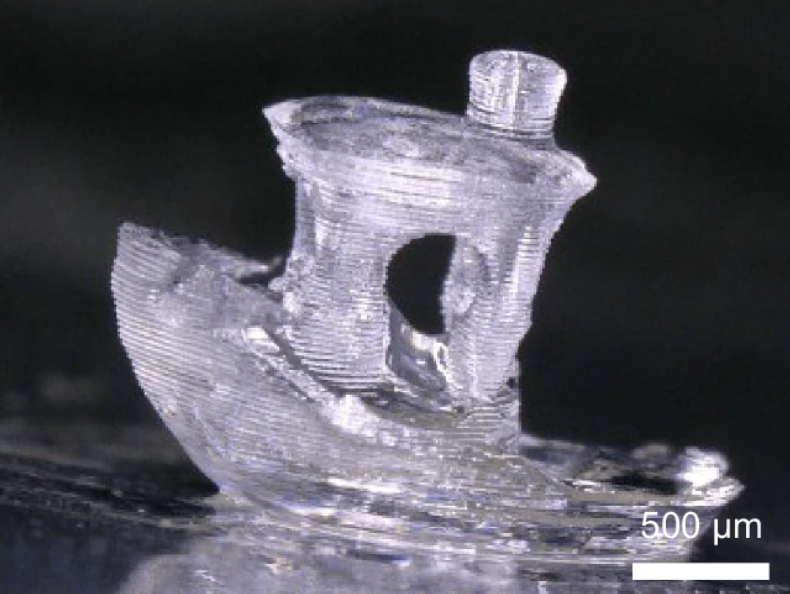

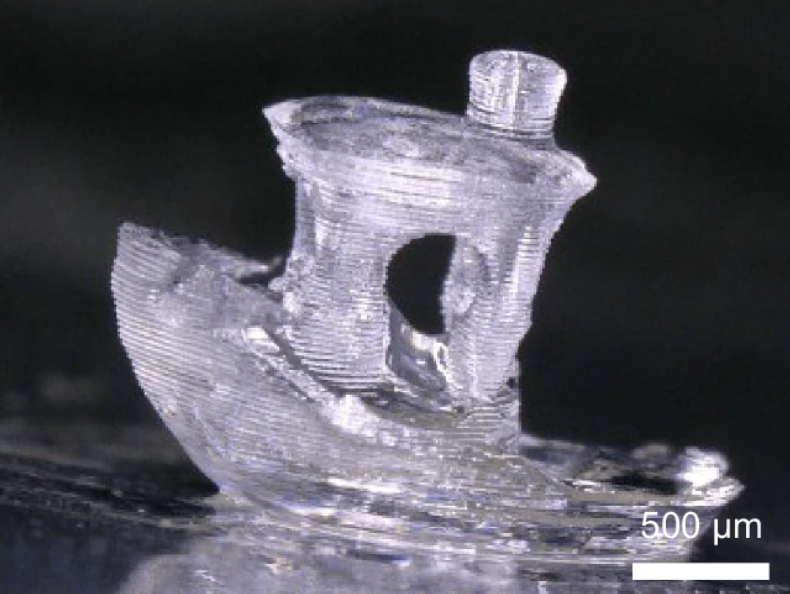

The researchers examined their novel technique utilizing a industrial polyacrylate resin and a hydrogel with embedded cells to 3D print a spread of high-resolution objects. These included 3D Benchy fashions, microscopic pillars, and lattice constructions.

Small particulars just like the Benchy’s sharp bow, hole cabin, and chimney had been properly preserved. One Benchy take a look at even showcased a 28.6 occasions enhance in mild effectivity, in comparison with typical strategies. Further take a look at prints, together with a cylinder with a gap, a Bucky Ball, and a Poporo artifact, had been printed in 37.03 seconds and 29.88 seconds, respectively. They exhibited spectacular high quality and floor end, confirming the holographic technique’s versatility.

The method was additionally efficiently utilized to hydrogels containing dwelling cells. The researchers discovered that utilizing Bessel and Vortex self-healing beams improved 3D print high quality and penetration depth in these mushy, scattering supplies. Moreover, not like typical strategies, no digital correction of projection patterns was wanted, highlighting its worth for biomedical functions.

Analysis unlocks 3D bioprinting breakthroughs

3D bioprinting is a key focus amongst lecturers, with many establishments working to optimize this beneficial course of. Certainly, the HoloVAM crew shouldn’t be the one group pursuing volumetric printing for biomedical functions.

Scientists at UMC Utrecht beforehand made a number of key improvements on this discipline. These embody creating biologically practical areas in 3D printed cells, optimizing bioprinted cells with granular gels, and 3D printing blood vessels utilizing volumetric bioprinting and soften electrowriting. The crew hopes these breakthroughs will pave the best way for expanded medical use of 3D bioprinting.

Elsewhere, researchers from Collins BioMicrosystems Laboratory on the College of Melbourne launched a brand new 3D bioprinting method known as Dynamic Interface Printing (DIP). Not like layer-by-layer approaches, DIP makes use of acoustic waves to information cells into exact configurations, permitting advanced, 3D printed human tissues to be fabricated in seconds. This reportedly affords the potential for custom-made, high-fidelity tissue constructions that supply worth throughout regenerative medication and illness modeling functions.

Who received the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade publication to maintain up with the most recent 3D printing information.

You can too comply with us on LinkedIn, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Featured picture exhibits a 3D Benchy fabricated utilizing holographic 3D printing. Picture by way of Nature Communications.