For producers, automation is now not a luxurious—it’s a necessity. However relating to automated palletizing, complexity may be the enemy of effectivity. On this unique dialog, John, a world director at a serious meals company, shares why his firm is transferring away from large-scale customized integrations in favor of modular, scalable options that ship quick ROI and long-term flexibility.

Strategic Funding in Automation – Low-risk with fast value financial savings

As companies navigate financial uncertainty and rising rates of interest, John emphasised the significance of prioritizing low-risk automation options with fast value financial savings.

“Excessive-risk, long-duration tasks with potential for substantial good points will not be our desire in the meanwhile,” he acknowledged. As an alternative, his firm is specializing in end-of-line palletizing options that combine seamlessly into present workflows with out requiring intensive reconfigurations—guaranteeing minimal disruption to downstream operations.

.png?width=408&height=408&name=Untitled%20design%20(4).png)

The Problem of Engineered Options

John highlighted the complexities of engineered automation options, noting that whereas they’re helpful for high-volume manufacturing strains, they typically require intensive customization that may shortly double the finances.

“Massive, custom-made integration tasks appeal to extra scrutiny and opinions, making it tougher to keep up simplicity and management over the venture’s scope.” – says John.

The inflexible nature of those options additionally makes future upgrades or modifications difficult, reinforcing the necessity for extra adaptable automation methods.

The Energy of Modular & Incremental Automation

John’s firm favours modular and incremental automation, which gives larger flexibility whereas sustaining effectivity.

“These options could have decrease payloads and longer cycle instances, however they’re budget-friendly, low-risk, and designed to suit inside present operations with out requiring main reconfigurations,” he famous.

By implementing smaller, faster automation tasks, his firm could make higher use of obtainable capital, particularly when bigger tasks expertise delays. For a step-by-step information on modular and incremental automation, try our Lean Robotics Methodology.

Sensible Recommendation for Firms Looking for Automation

When requested about deciding on the precise palletizing options, John pressured the significance of conserving it easy.

“Go for customary, dependable, and strong options. Consider automation as an ongoing program slightly than remoted tasks. Keep in mind, palletizing is about transferring packing containers— so don’t overcomplicate it.”

He suggested corporations to deal with fast wins and low-risk options to construct momentum and confidence in automation.

Consciousness & Adoption of New Robotic Applied sciences

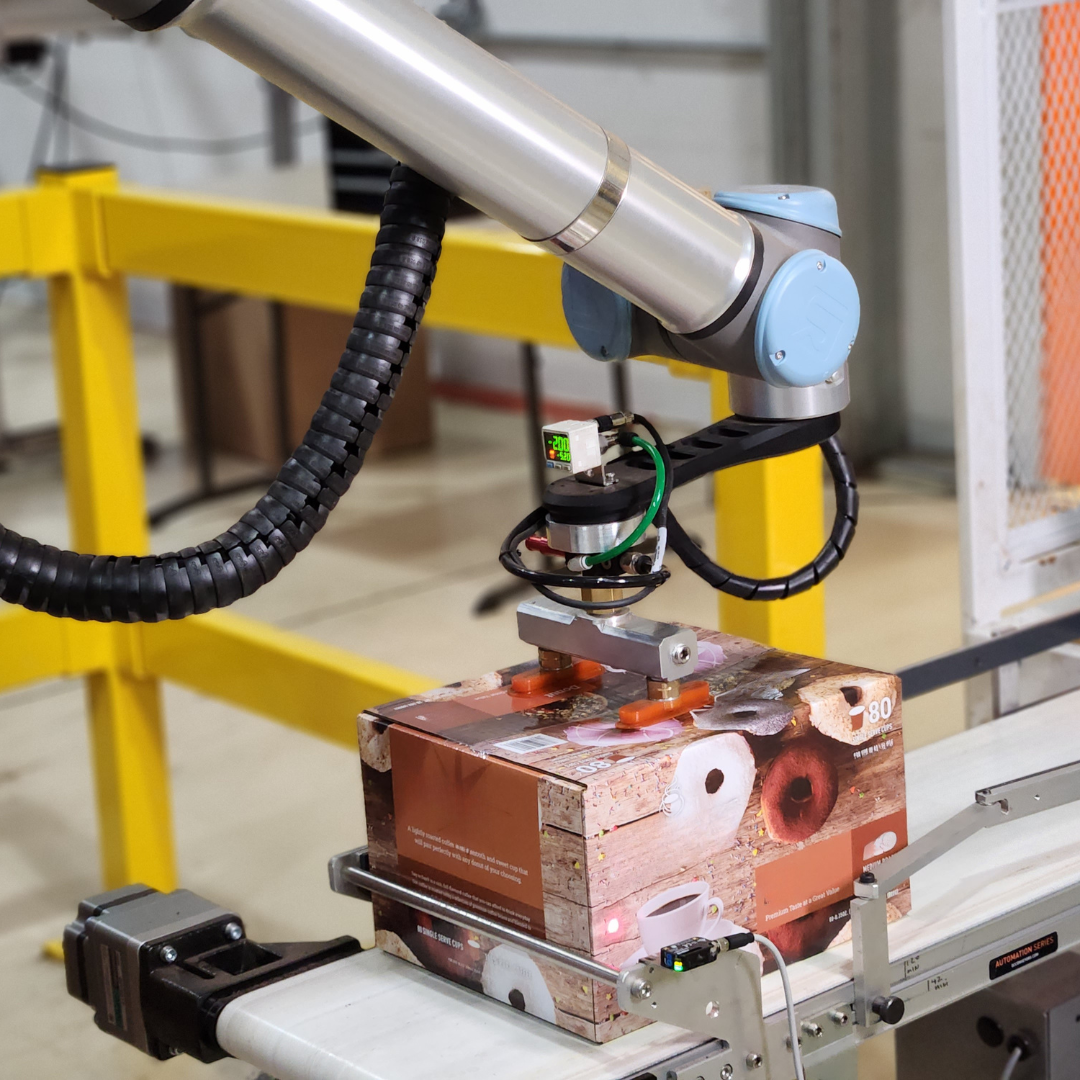

John additionally identified that many companies are nonetheless unaware of the accessibility of collaborative robots (cobots), which require much less ground house and fewer infrastructure modifications than conventional automation options. He cautioned towards pointless venture expansions pushed by system integrators trying to improve scope and complexity. Understanding all out there automation choices and guaranteeing alignment with enterprise objectives is essential for profitable implementation.

The Evolving Narrative of Automation

John mirrored on how the motivation for automation has developed. “Prior to now, automation was typically pushed by worry of lacking out. Immediately, it’s about value financial savings, modernization, and office enchancment, all whereas sustaining monetary viability in a time of constrained capital,” he stated.

His firm’s technique has shifted towards prioritizing quite a few small, standardized automation options that ship constant financial savings and effectivity. In an unpredictable world, automation should not solely scale back prices but in addition present flexibility to adapt and thrive amid fixed change.

Conclusion

John’s insights underscore a key message for producers: automation ought to be sensible, scalable, and targeted on actual effectivity good points. By selecting modular, standardized options, corporations can guarantee fast returns, preserve operational agility, and create a basis for long-term success.

As automation continues to evolve, embracing good, adaptable options will probably be vital for navigating at the moment’s dynamic enterprise atmosphere.